STIHL Chains and Guide Bars: The Perfect Combination

Discover why STIHL saw chains and guide bars deliver unmatched precision, innovation, and performance for every cutting challenge.

09.10.2025

Precision and Performance in Every Cut

When you’re working outdoors, your equipment needs to withstand demanding conditions. That’s why STIHL chains and guide bars are engineered for strength, balance, and precision. Manufactured with advanced technology and quality control, they ensure smooth operation, optimal lubrication, and long service life.

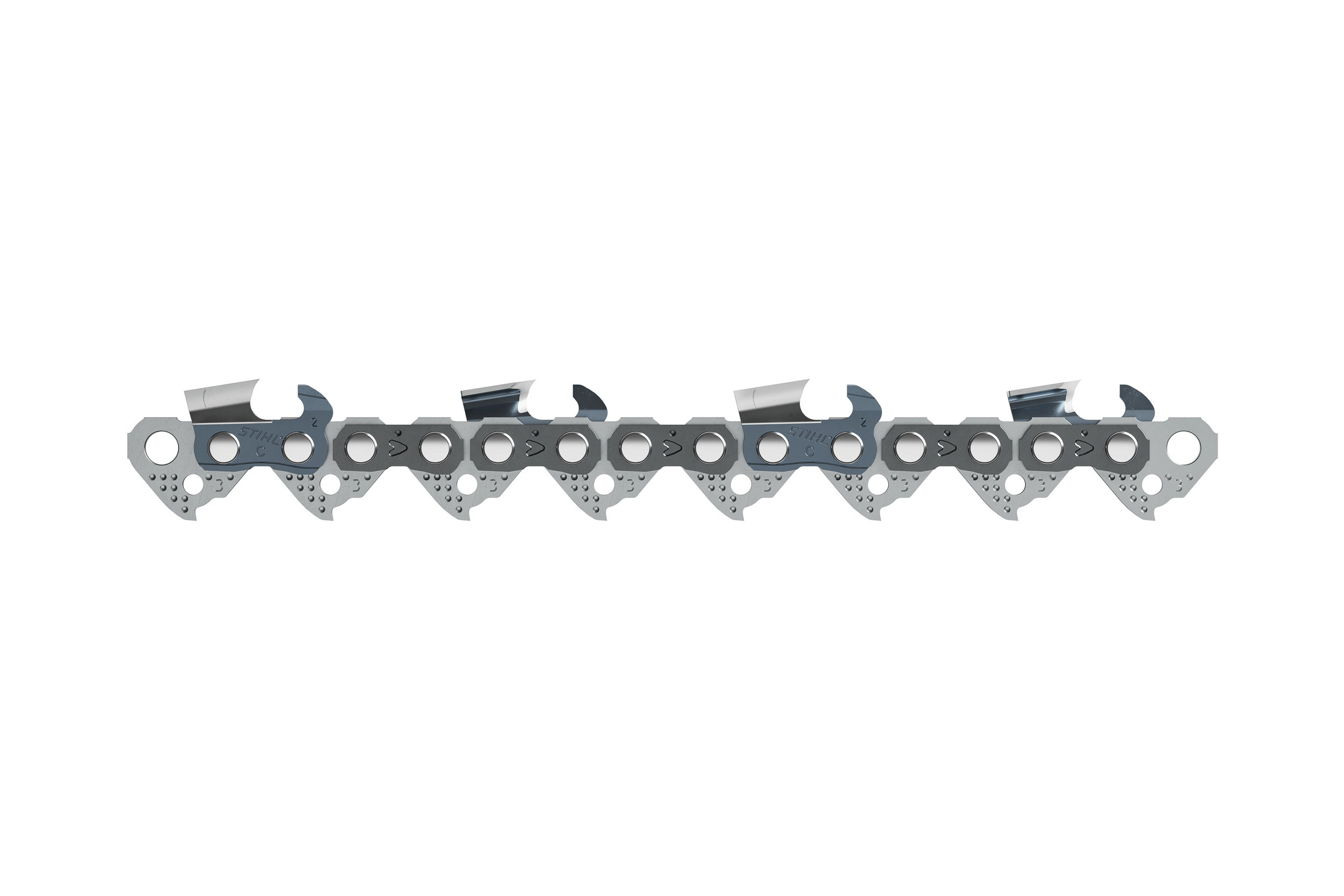

STIHL Saw Chains: Precision from Switzerland

STIHL saw chains are produced in Wil, Switzerland, using specialised in-house machinery to guarantee world-class consistency and performance. Every chain is designed for clean, efficient cutting across every saw class and brand.

- Advanced Lubrication System: Chain drive links include oil reservoirs and channels for even lubrication, reducing friction and wear.

- Hardened Steel Teeth: Each cutter tooth is galvanised for increased durability and long-lasting sharpness.

- Pre-Stretched Design: Every chain is pre-tensioned to reduce initial stretching and maintenance time.

- Low-Vibration Comfort Chain: Identified by the “C” mark, vibration is reduced by up to 70% for smoother operation.

- Integrated Sharpening Guide: Tooth markings indicate wear limits and sharpening points for ease of maintenance.

STIHL Product in Focus: .325” Pro Saw Chains

The .325” Pro Saw Chain series offers up to 20% improved cutting performance compared to standard .325" chains. This performance boost is achieved by reducing the kerf width on the top plate, enabling faster cutting with less effort.

STIHL Guide Bars: Light, Robust, and Innovative

STIHL guide bars are designed for precise manoeuvring, low friction loss, and maximum durability. Each bar undergoes electromagnetic induction hardening for superior wear resistance and features the STIHL Ematic system to reduce chain oil use by up to 50%.

- Rollomatic Series: Sprocket nose with sealed bearings for low wear and long life.

- Reversible Design: Fully symmetrical bar shape for even wear and extended lifespan.

- Lightweight Construction: Rollomatic E Light and ES Light bars reduce weight using hollowed, reinforced steel designs.

Guide Bar Types: Rollomatic E, Rollomatic ES, Duromatic

- Rollomatic E: Lightweight, welded 3-plate construction for chainsaws up to 3.5 kW. Lengths 25–63 cm.

- Rollomatic ES: Solid body with replaceable nose for professional saws above 3.5 kW. Lengths up to 150 cm.

- Duromatic: Heavy-duty steel body with carbide-plated nose for maximum endurance in high-performance saws.

STIHL Product in Focus: Light 04 Guide Bars

The STIHL Light 04 Guide Bar offers improved balance, lower kickback, and up to 200 g less system weight. Designed for the MS 261 and MS 271 powerheads, this bar enhances cutting control and operator comfort without compromising strength.

Summary: STIHL Chains and Guide Bars

- All STIHL chains and guide bars are developed and produced in-house.

- Every chain and bar is designed for optimal compatibility and longevity.

- STIHL chains can also fit many chainsaws from other manufacturers.

- Guide bars include Rollomatic E, Rollomatic ES, and Duromatic types.

- Lightweight and comfort variants improve efficiency and user experience.